Lavelle hubs

We think differently

All Lavelle hubs feature our own Micron Technology

Road/Gravel 100-142

MTB / Enduro 110-148

BMX

Low Drag System

While aerodynamics and weight are often prioritised in the bicycle industry, drag can negate these gains if not properly addressed. Our design focuses on minimizing drag to the lowest possible degree.

The titanium axle maintains bearing alignment, while our special seal design and bearing selection work in harmony to reduce friction. Thanks to our meticulously engineered hubs riders consistently report a dramatic improvement in their rides.

Angel Suarez

DH World Cup Racing @Frameworks

Photographer Kike Abelleira

Titanium

Titanium rolling chassis

The hub is the heart of the bicycle’s rolling system, connecting the bike, rider, wheels, and ground. Only four bearings handle this critical task, and for optimal performance, they must be perfectly aligned and perpendicular to the axle at all times. We’ve chosen titanium axles for all our hubs due to their tenfold strength advantage over aluminum. This ensures a rigid foundation for our rolling system, a core aspect of our design.

Ti 65% stiffer and 300% stronger than aluminium.

Premium Bearings

Extensive research has gone into selecting the optimal bearings for our hubs. We use larger bearings than most manufacturers, as they provide minimal drag and significantly improve performance and reliability.

In partnership with SKF, we supply best-in-class bearings that deliver twice the efficiency, double the strength, and a 20% reduction in drag compared to competitors.

Micron engagement

Our MTB customers particularly value our instant pedal engagement feature, but all riders benefit from this innovation. With no moving parts, our clutch system offers exceptional durability and engages within just 0.2 degrees of pedal rotation. This provides a solid, connected feel, giving riders the control they need precisely when they need it.

Seals Barrier

Effective hub and bearing sealing is straightforward if drag is disregarded.

However, our commitment to low drag led us to design a triple barrier system that effectively keeps out debris while maintaining low friction, ensuring long-lasting performance.

Direct axial bearing Preload

Precise bearing preload is crucial for low rolling resistance and eliminating unwanted play. After countless hours of design and testing, we’ve developed a system that does not require a meticulous setup during assembly but still delivers exact preload for the bearings.

Optimized flange

Our unique flange design is the result of careful FMEA (Failure Modes and Effects Analysis) and testing. We’ve removed unnecessary material to reduce weight while creating an aesthetically pleasing hub design.

Reinforced brake interface

The ISO 6-bolt interface is the most widely used option for MTB brake discs.

Our specially designed connection flange provides significantly greater stability and torsional stiffness, resulting in a vastly improved braking experience.

Also improving aerodynamics around the threads area.

Anodized Surfaces

To extend surface longevity, we use high-quality Type 2 hard anodization, which offers superior surface protection.

The precise treatment process allows us to anodize even bearing contact points without post-machining, resulting in a stronger and more durable solution.

Highly durable system

Lavelle´s entire hub system is engineered for maximum durability, utilising a titanium chassis and top-grade materials.

With class-leading Ti Gr 5 and Aluminum 7075 T6, our hubs have proven their resilience in world championship downhill races, enduring without damage or failure.

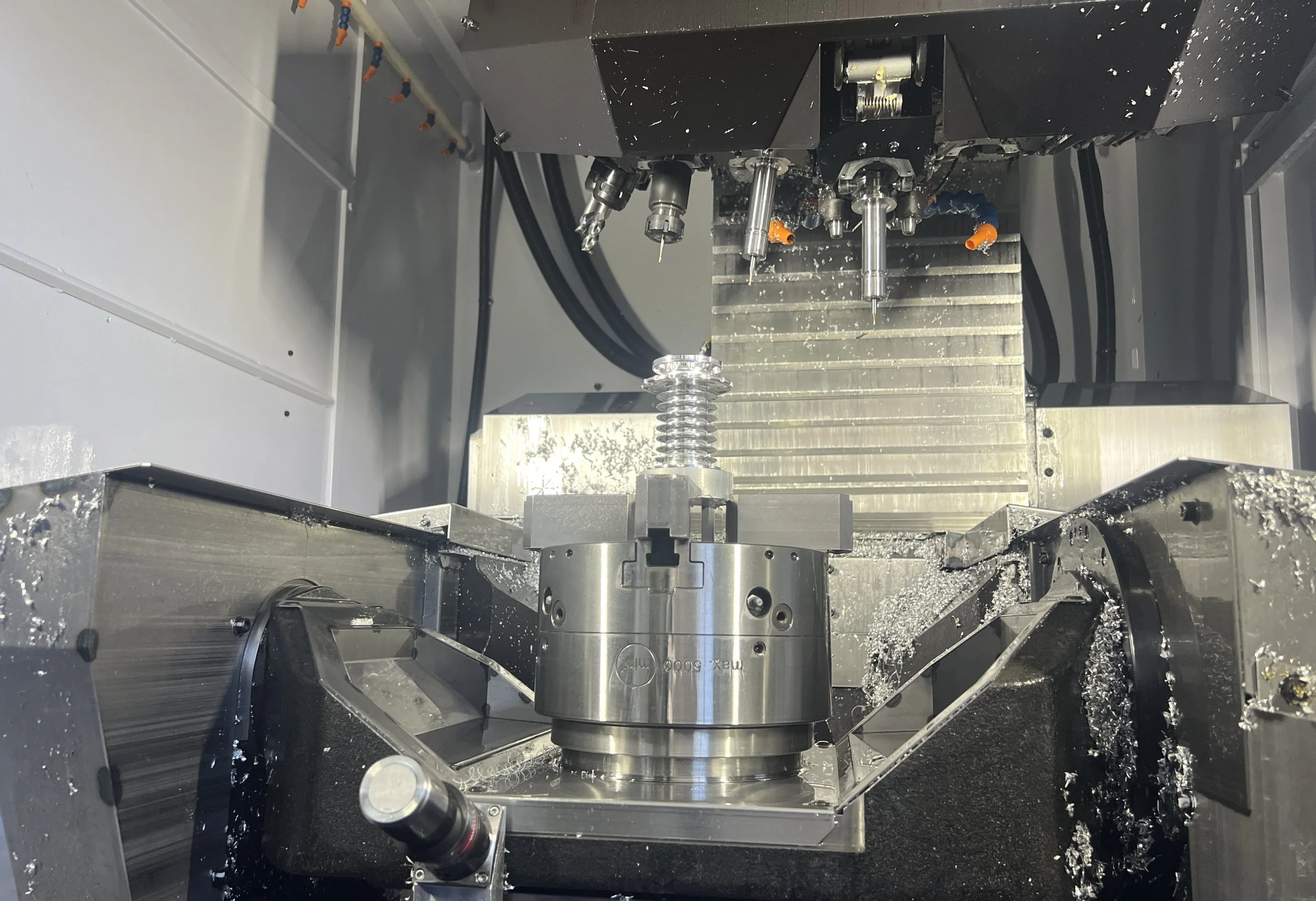

Micron level machining

We adhere to aerospace machining tolerances, a critical factor in achieving our ultra-smooth, highly efficient, low-drag system.

Ultra simple

maintenance

We believe that our commitment to quality and purpose-driven design makes breakdowns on the trail unlikely. However, we’ve also ensured that disassembly and servicing are simple and can be performed without any tools.

Our use of industrial bearings means worldwide availability, should the need arise.

Proven design

Originally designed for our Fireroad carbon fiber wheels, our hub has been tested and proven in some of the world’s toughest race conditions, like Traka360 and Midnight Race in Norway delivering flawless performance under extreme demands.

Hub specification

Front 100 mm

Axle 12 mm

Front 110 mm

Axle 15 mm

Rear 142 mm

Axle 12 mm

Rear 148 mm

Axle 12 mm

Transmission

0.2º Engagement

Silent coast

Brake

Centerlock

ISO 6 Bolt

Drive shell

SRAM XD/XDR

Shimano MS 9 Splines

Spokes

Bearings

24 Holes J Bend

28 Holes J Bend

61902 Front

ø15 mm axle

61903 Front

ø17 mm axle

61903 Rear

ø17 mm axle

61903 Rear

ø17 mm axle

MTB/ Enduro /DH

Road / Gravel

Geometry

32 Holes J Bend

Weight

Front 110g

Front 140g

Rear 310g

Rear 340g

Range of our Micron Technology hubs

Road/Gravel 100-142

MTB / Enduro 110-148

BMX

Fireroad Review JY C